By Brandon Lewis, Embedded Technology Industry Analyst

Software-defined manufacturing (SDM) represents one of the final stages of complete IT/OT convergence by connecting enterprise cloud and data center services to industrial edge sensors and controllers. With end-to-end infrastructure in place and multi-function, converged infrastructure platforms operating at or near endpoints, workloads can be orchestrated from edge to cloud with increased efficiency and reduced effort as one would find in a datacenter.

SDM is the realization of Industry 4.0, where cyber-physical systems rely on real-time data to operate with various levels of autonomy in pursuit of never-before-experienced levels of uptime, productivity, and cost savings. But, until recently, SDM was little more than a concept because of the separate networking and business requirements of IT and OT domains that prevented converged networks from unifying the two classes of systems.

Time-Sensitive Networking (TSN) changes all of that.

Enabling Time-Sensitive Networking for All

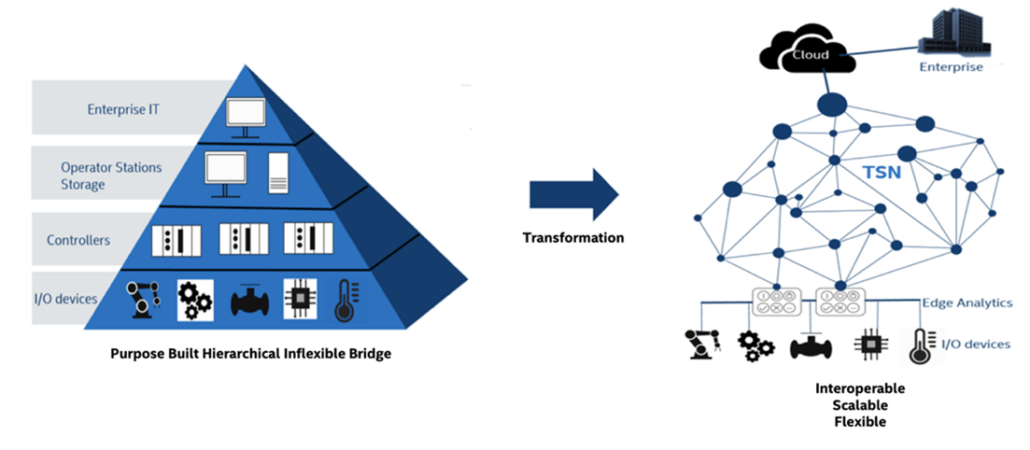

TSN is a set of IEEE 802.1 standards that support time-synchronized packet transport over the type of deterministic networks you’d find in a factory. By enabling accurate timing, traffic scheduling, and resource-allocation across a real-time network, TSN serves as the connective tissue required to make concepts like SDM a reality.

TSN standards are based on Ethernet, but at the same time provide an ultra-reliable, low-latency connectivity transport that supports multiple traffic classes and serves as a highly scalable, interoperable networking foundation for Industry 4.0. It allows IoT operators to seamlessly integrate cyber-physical systems, IoT devices, and cloud services. More importantly, it helps them manage all this as part of a single, coherent, virtualization-ready infrastructure.

Of course, the standards are still evolving and implementing a TSN network requires much more configuration than simply plugging in an Ethernet cable. Now, a collaboration between industry leaders Intel®, TenAsys®, and Kontron is yielding TSN-enabled hardware and software stacks that abstract the complexity of converged real-time Ethernet networks, support the consolidation of different mixed-criticality workloads onto a single edge computing platform, and put SDM firmly within reach.

“There are a number of things in the TSN standards that need to be implemented to make the whole thing work, but there is a shortlist of people in the world who know how to do that right now,” says Kim Hartman, VP of Sales & Marketing at TenAsys, developers of the first TSN real-time operating system (RTOS). “By nature of integrating TSN into our stack, we’re doing the heavy lifting and providing something that just works out-of-the-box. It’s something a developer can pick up and run with.”

“This is why we have interest and are taking a lead position in TSN—to enable an RTOS to have TSN services,” Hartman continues. “This is democratizing so that anybody who has an interest in SDM, for instance, can come in and pick up the INtime® RTOS and run with it. They can keep their head in the solution space instead of inside TSN.”

[Figure 1 | With TSN, hierarchical networks can be transformed into flexible networks that integrate the enterprise and edge in a highly scalable manner.]

Time Synchronization for Software-Defined Manufacturing

As automation technology continues to advance, modern systems rely more on software than dedicated, proprietary hardware. With TSN-enabled SDM and an RTOS like INtime, operators can centrally manage their entire infrastructure using software workloads and commands that can be deployed anywhere on the network at any time.

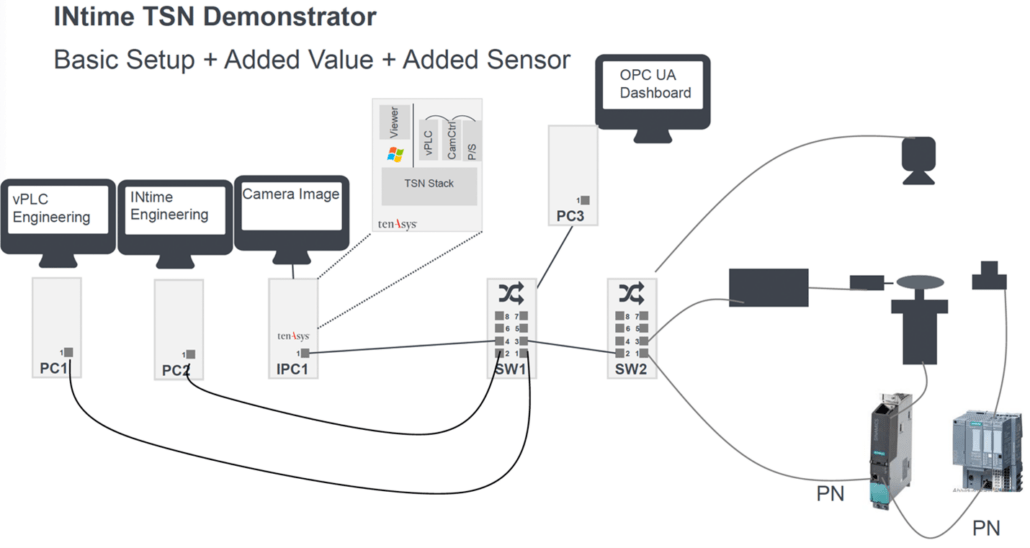

For example, consider the TenAsys TSN demonstrator system (Figure 2). Such a system represents an application like an automated visual inspection system, which depends on low-latency communication to ensure production line determinism. A stepper motor driving the control application needs to be on the factory floor where it is being used, but the PLC controlling the motor can be an edge appliance located anywhere on a TSN-based network.

[Figure 2 | This diagram shows how Time-Sensitive Networking (TSN) technology enables the distributed deployment of control functions at remote points on a network. (Source: FISW Steuerungstechnik GmbH)]

In addition, a camera—independent of the motor and PLC—can monitor the system and the work the motor is performing. Data from the camera can be streamed to the cloud or enterprise for AI processing, and the analysis can then be passed back down to the PLC to improve operations, all without impacting PLC communications latency.

This is just a representative example. The applications with TSN are endless, offering incredible deployment flexibility that is highly scalable. More sophisticated use cases such as collaborative robots, augmented reality for maintenance, and automated quality control become possible at a broader scale with SDM over TSN.

[Note: Read the insight.tech article, “Time-Sensitive Networking Poised to Transform Industrial IoT”]

Simplifying Network Convergence for a Broad Range of Applications

TSN fundamentally changes how industrial applications can be deployed. Rather than adopting specialized, often proprietary edge hardware, general-purpose multicore control platforms can be selected and deployed independently. This enables manufacturers to optimize their equipment selection and also deploy that equipment anywhere across their infrastructure—regardless of proximity to sensors and actuators.

For example, in a TSN-enabled SDM deployment, all PLCs can be virtualized (vPLCs), consolidated, and co-located off the factory floor to protect from environmental factors such as vibration and heat. It can also improve security by positioning critical systems behind locked doors and simplify management and maintenance by concentrating devices in a single room instead of dispersed across a campus.

Note that TSN achieves this by simplifying the network rather than adding additional layers of complexity. TSN-enabled network components address many of the challenges associated with deploying and managing real-time distributed networks. This reduces implementation complexity and the need for specialized domain expertise, thereby reducing total cost of ownership and time to market.

How Intel®, TenAys®, and Kontron Hook Mixed-QoS TSN Workloads to Hardware

A software-defined environment requires precise time for resource coordination and management to account for required application latencies. Intel® Time Coordinated Computing (Intel® TCC) is the combination of modern software and real-time capabilities, an emerging technology on select Intel® platforms that provides optimizations and features that make precision timing available to the management of software, cache memory, I/O, and other local resources. The TenAsys® INtime® RTOS utilizes TCC capabilities to synchronize its TSN stack and ensure the determinism that is required to interface real-time workloads with TSN networks.

Intel TCC and the INtime RTOS can be combined with TSN-based Ethernet switches such as the Kontron KSwitch D10 MMT Series to guarantee low latency, jitter, and quality of service (QoS) for real-time manufacturing use cases. From here, manufacturers just need to “connect” real-time systems and TSN takes care of the rest—even when the network carries “mixed” traffic (i.e., control traffic and non-real-time data).

As Greg Schlechter, Senior Director of Technology Strategy at Intel explains, the TSN-Intel TCC-INtime RTOS stack provides “a predetermined channel to speak over an enterprise network that is also deterministic and reliable.”

“Sharing control information or data that is part of a control loop between compute systems is possible,” Schlechter continues. “And now you’re heading towards something that is truly a distributed network of [synchronized] compute controllers.”

The Future of Manufacturing is Deterministic and Software-Defined

Traditionally, manufacturing systems have been proprietary and OEMs would have to buy an entire networked system of systems from a single vendor. Because these solutions are typically based on proprietary protocols, their systems are rendered incompatible with other similar systems available from other vendors.

Now, TSN makes it possible to select most appropriate components for a particular application from a diversity of vendors adhering to the converged TSN standards. OEMs can work with off-the-shelf components rather than invest in full-custom solutions. It also increases OEM’s access to a wide variety of tools and support across the ecosystem. In short, the new approach to manufacturing makes it easier for OEMs to benefit from advances in automation and the democratization of technology and standards.

TSN promises to bring a new level of precision and real-time responsiveness to manufacturing. It has the potential to democratize access to advanced industrial automation solutions, enabling manufacturers to finally make their long-awaited appearance on the digital transformation stage.

To learn more about TSN, read “Abstracting Configuration Complexity of Time-Sensitive Networking to Accelerate Mass Adoption”.